- Number of additives: 3 standard, 4 optional

- Injection Ratios: Three additives: (1) 0-1,500 PPM (2) 0-65 PPM Four additives: (1) 0-1,500 PPM (1) 0-275 PPM (2) 0-65 PPM

- Minimum injection ratio: 10 PPM standard

- Normal operating range: 100-1,000 GPM (378-3785 liters per minute)

- Minimum product flow rates: 50 GPM (189.21) (minimums vary with line pressure)

- Product temperature: 40°F to +250°F (-40°C - 121.1°C)

- Maximum product line pressure: 125 PSI (8.8 kg/cm) (PSI max varies with injection ratios, higher pressure pumps are available as options)

- Maximum hydrostatic pressure: 350 PSI (24.6 kg/cm)

- Product viscosities: to 10,000 SSU

- Products handled: oils, fuels, chemicals

- Duty cycle: continuous

- Fluid connections - product: 6” (15.24 cm) cam lock, additives: ¼” (.6 cm) NPT or ¾” (1.9 cm) NPT

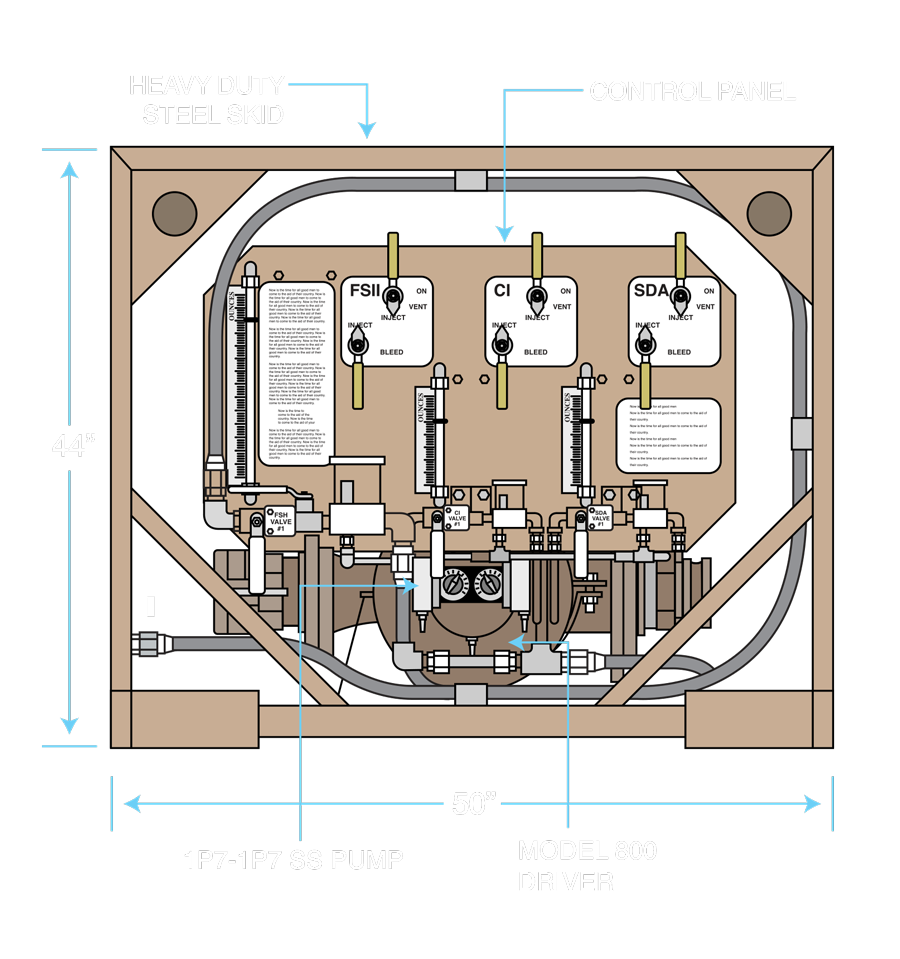

Model TPI-4T-4A-1

Model TPI-4T-4A-1

The TPI-4T-4A-1 utilizes Hammonds proven additive injection systems to produce military specification JP-8 jet fuel by injecting FSII, CI and SDA additives. Each additive is delivered continuously and is blended evenly at ratios from 4-2500 ppm.

- Accurate additive dosage

- Thorough, complete blending

- Easily transportable

- Sturdy, solid construction

- Available in a cart configuration

SPECIFICATIONS

CONSTRUCTION MATERIALS

- Fluid Motor: All hard anodized aluminum with stainless steel shaft

- Injectors: All wetted parts 300 series stainless steel with Teflon® trim

- Mechanical Seal: Carbon on ceramic

- Model 800 driver

Trusted by Industry Leaders Worldwide

For over three decades, Hammonds has been the global standard in additive injection technology, delivering innovative solutions that protect fuel systems across every continent.

0+

Systems Installed

0+

Countries Worldwide

0+

Years of Excellence